He aha ka Sintered Metal?

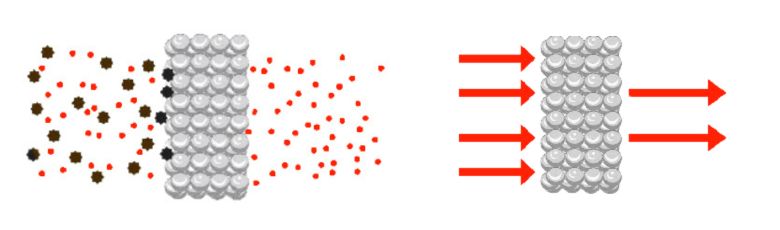

He aha ka Sintered Filter Working Principle ?

Pokole e ʻōlelo, No ka paʻa porous frame,nā kānana metala sinteredʻo ia kekahi o nā mea kānana maikaʻi loa

i kēia mau lā. Eia kekahi, hiki ke kōkua iā ʻoe i ka wela kiʻekiʻe o nā mea metala, ke kaomi kiʻekiʻe, a me ka pale ʻana i ka corrosion

e hoʻopau maʻalahi i ka hana kānana ma kahi ʻoi aku ka paʻakikī, Hoʻokaʻawale a kānana i nā mea haumia

ʻaʻole pono ʻoe a kōkua paha iā ʻoe e unuhi i nā kinoea maʻemaʻe kiʻekiʻe a i ʻole nā wai no kāu papahana, a inā ʻoe e ʻimi nei.

kekahi hale hana maoli i OEM sintered metala kānana no kāu ʻōnaehana kānana, e ʻoluʻolu e nānā maanei e ʻike

kaNā mea hana kānana ʻoihana kiʻekiʻe.

ʻAʻole paha ʻoe e lohe nui i kēia ʻōlelo i kou ola i kēlā me kēia lā.

Akā i kēia mau lā, ua hoʻohana ʻia ka metala sintered e hoʻohana hou aʻe i nā ʻoihana like ʻole.

kaʻenehana kī i kekahi hana.

A lailaHe aha ka Metala Sintered?

ʻOiaʻiʻo, he lālā ia o ka ʻoihana metallurgy pauka, i ka pōkole, ʻo ia ka 316L stainless steelpauda ma ka poʻi

ka hoʻohua, kiʻekiʻe wela sintering i loko o ke kinona a me ka hana o ke kaʻina hana a mākou e pono ai.

A laila, ka mea mua, sintered.He aha ka mea i hoʻopaʻa ʻia?

ʻO ka Sintering ka hana o ka hoʻopaʻa ʻanaa me ka hana ʻana i kahi paʻa paʻa omea waiwai

ma ka wela a i ʻole ke kaomi ʻana me ka hoʻoheheʻe ʻole ʻana a hiki i ka liʻiliʻi. He ʻāpana o ka Sinteringhe hana hana i hoohanaia

me nā metala, seramika,nā plastic, a me nā mea ʻē aʻe.Wikipedia

E like me ka wehewehe ʻana o Wikipedia, hiki ke hoʻopaʻa ʻia nā ʻano mea like ʻole, a loaʻa nā ʻano mea like ʻole

ʻokoʻanā noi. A laila makemake mākoue kamaʻilio hou aku e pili ana i ka metala sintered.

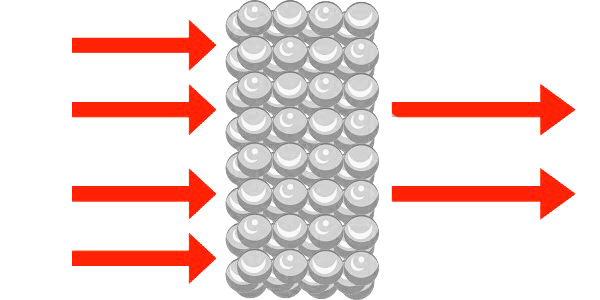

1. Hoʻokaʻawale ʻana a me ka hoʻokaʻawale ʻana 2. Kaohi wai

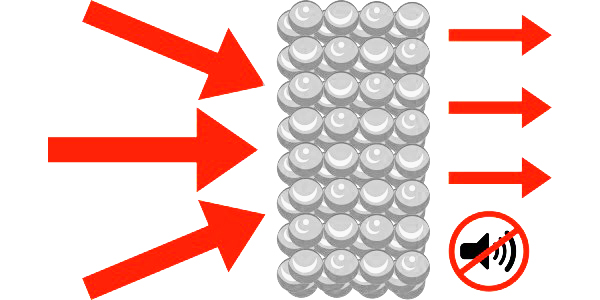

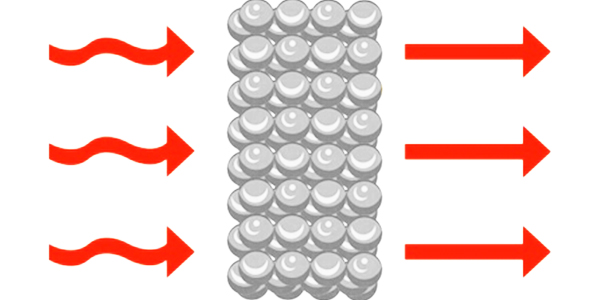

3. Hoʻemi ʻia ka walaʻau 4. Kahe paʻa

Mooleloo Sintering Metal

ʻO wai ka mea i hana i ka sintering a hoʻomaka e hoʻohana i nā huahana sintered?

Wahi a nā moʻolelo mōʻaukala, ua puka mai ke kaʻina hana sintering i ka lua o ka hoʻololi ʻana o ka ʻenehana i ke kenekulia 18

ma Suedenaa me Denemaka. ʻO ka hao i hoʻopaʻa ʻialoaʻa i ka wā o ka hoʻoheheʻe ʻana i nā lua lanahu. Akā a hiki i 1980, poʻe

hoʻomaka e hoʻohana i kametala sintered i ka aila kānana. A no 1985, ka HyPulse® mua i hoʻohanaʻenehana kānana no

kānana aila slurry mau.

No laila, hiki iā ʻoe ke nānā e like me ka hahai ʻana, aia nā manawa 3-hoʻomohala nui.

1. Kahiko

* Makahiki keleawe:

ʻO ka hōʻike mua loa o nā kaʻina hana sintering mai ka Bronze Age, kahi i loaʻa ai nā mea metala

hana ʻia paha e ka hoʻomehana ʻana a me ka hoʻoomi ʻana i nā pauka metala.

* Makahiki hao:

Ua hoʻohui ʻia paha nā ʻenehana hana hao, me ka hoʻohana ʻana i ka hao hao i hoʻomehana ʻia a hoʻopaʻa ʻia

nā mea o ka sintering.

2. Industrial Revolution and Early Developments

* Ke kenekulia 19:

Ua ʻike ka Industrial Revolution i ka nui o ka hoihoi i nā ʻenehana hana metala. ʻO ka pauka metala,

he mea mua i ka sintering, ua hoʻomaka e puka ma ke ʻano he ala no ka hana ʻana i nā mea metala mai nā mea pauda.

* Ka Makahiki 20th Century:

ʻO ka holomua o ka metallurgy a me ka ʻepekema waiwai i alakaʻi i nā hoʻomohala hou i nā ʻenehana sintering.

ʻO ka hana ʻana o nā kānana metala porous a me nā bearings me ka hoʻohana ʻana i nā kaʻina sintering i lilo i mea maʻamau.

3. ʻO ke au hou a me ka holomua ʻenehana

*Iwaena o ke kenekulia 20:

Ua ulu nui ka ʻenehana Sintering i ka waena o ke kenekulia 20, i alakaʻi ʻia e nā holomua

i ka pauda metallurgy a me ka ʻepekema waiwai. ʻO ka hoʻomohala ʻana i nā mea sintered kiʻekiʻe no ka

Aerospace, automotive, a me nā noi ʻoihana i lilo i mea nānā.

* Ka hopena o ka 20th a me ka 21st Century:

ʻO ka hopena o ka 20th a me ka hoʻomaka ʻana o nā kenekulia 21 i ʻike i ka hoʻomau ʻana i ka ʻenehana sintering. ʻO ka hoʻomohala ʻana

ʻO nā ʻano hana hoʻoheheʻe kiʻekiʻe, e like me ka selective laser sintering (SLS) a me ka binder jetting, hoʻonui i ka laulā.

nā mea a me nā ʻano paʻakikī i hiki ke hana ʻia.

Nā noi o kēia wā

*Kaʻa:

Hoʻohana nui ʻia nā mea Sintered i nā ʻāpana automotive, me nā mea hoʻokele, nā bearings, a me nā kānana.

ʻO kā lākou mau waiwai, e like me ka ikaika, ka lōʻihi, a me ka porosity, e kūpono iā lākou no nā noi koi.

*Aerospace:

Hoʻohana ʻia nā mea Sintered i nā ʻāpana aerospace ma muli o ko lākou māmā, ikaika ikaika.

Loaʻa iā lākou ma nā ʻāpana e like me nā lau turbine, nā nozzles wahie, a me nā mea hoʻololi wela.

* Nā Mea Lapaʻau:

Hoʻohana ʻia nā mea sintered i nā ʻano lāʻau lapaʻau like ʻole, me nā implants, prosthetics, a me nā mea niho.

ʻO kā lākou biocompatibility a me nā waiwai maʻamau e kūpono iā lākou no kēia mau noi.

* Nā noi ʻoihana:

Loaʻa i nā mea i hoʻopaʻa ʻia he nui nā noi ʻoihana, me ka kānana, ka uila, a me ka mālama ʻana i ka ikehu.

ʻO kā lākou versatility a me nā hiʻohiʻona hana e waiwai ai lākou i nā ʻano ʻoihana ākea.

Ka hopena

Eia nō naʻe, ua ulu nui ka ʻenehana Sintering i nā kenekulia, mai kona kumu kahiko a hiki i kāna mau noi hou.

Ma o ka holomua mau i ka ʻepekema waiwai a me nā kaʻina hana, ua lilo nā mea sintered

nā mea koʻikoʻi i nā ʻoihana like ʻole, e hāʻawi ana i ka holomua ʻenehana a me ka hana hou.

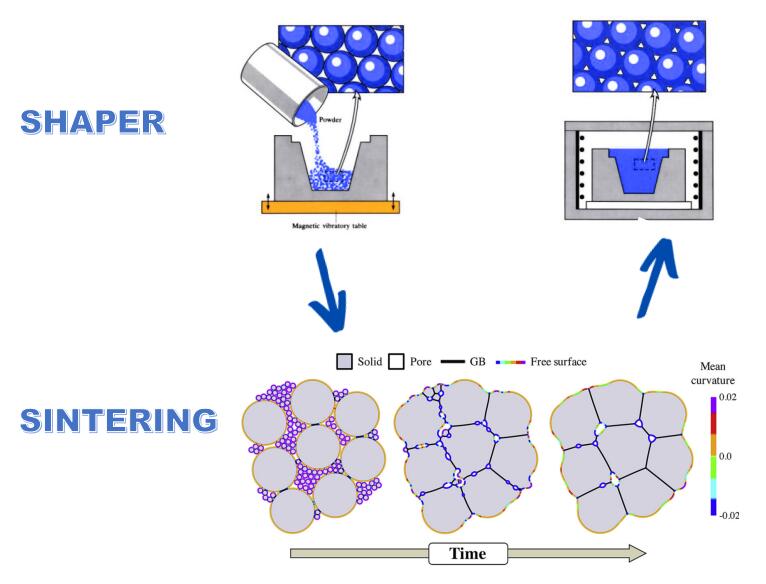

No laila he aha ka Sintered Metal Filter?

He wehewehe maʻalahi o ke kānana metala sintered:

He kānana metala ia e hoʻohana ana i nā ʻāpana pauda metala o ia meanui ʻāpanae hana ʻia me ke kahakaha ʻana,

kiʻekiʻe-mehana sintering kaʻina. ʻO ka Sintering ka hana ometallurgy e hoʻohana ana i ka paudakino o

nā metala ʻokoʻa a me nā ʻāpana ma hope o ke kaha ʻana.

Hana ʻia ka metallurgy ma ka hoʻopuehu ʻana i nā mahana ma lalo o ka helu heheʻe o nā umu wela wela.

ʻO nā metala a me nā mea haohoʻohana mau ʻia i kēia lāe komo pū me ka aluminika, ke keleawe, ka nikela, ke keleawe, ke kila kila,

a me ka titanium.

Aia nā kaʻina hana like ʻole hiki iā ʻoe ke hoʻohana i ka hana ʻana i ka pauka. ʻO ia ka wili, atomization,

a me ka decomposition kemika.

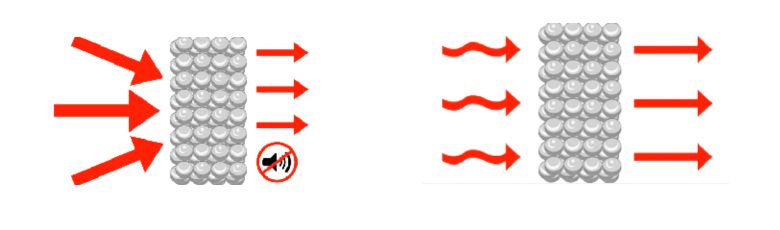

He aha ka Sintering Kaʻina Hana Hana Metala kānana

A laila, maʻaneʻi, makemake mākou e nānā i ke kaʻina hana o ka hana kānana Metal. inā makemake, e ʻoluʻolu e nānā i lalo:

1.) He aha ka Sintering, No ke aha e hoʻohana ai i ka Sintering?

ʻO ka sintering wehewehe maʻalahi ka pauka metala i hoʻopaʻa ʻia e ka wela kiʻekiʻe a me nā ʻano hana ʻē aʻe i loko

ka module i makemake ʻia.Ma ka laulā micron, ʻaʻohe palena kino ma waena o nā ʻāpana pauka metala,

ʻo ia ke kumu e hiki ai iā mākou ke hoʻomalu i ka mamao o ka pore

ma o ke kaʻina hana.

Hāʻawi ka pahu pahu porous o ke kaʻina sintering i ke ʻano paʻa o ka metala a hāʻawi

ka mea me kaka hana o ka kānana ikaika.

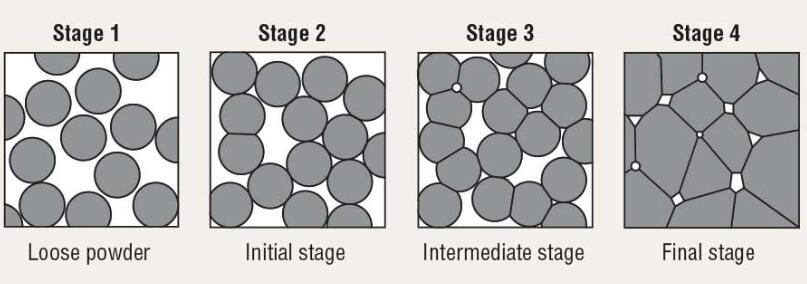

2.)3-MainNā ʻanuʻu o ka Sintered Metal Filter Manufacturing

A: ʻO ka hana mua ka loaʻa ʻana o ka metala mana.

ʻO ka pauka metala, hiki iā ʻoe ke loaʻa i nā pauka metala ma ka wili ʻana, atomization, a i ʻole decomposition kemika.

Hiki iā ʻoe ke hoʻohui i hoʻokahi metalaka pauda me kekahi metala ʻē aʻe e hana ai i mea hoʻohui i ka wā o ka hana ʻana,

a i ʻole hiki iā ʻoe ke hoʻohana i hoʻokahi pauda. ʻO ka maikaʻi o ka sintering ʻo iaʻaʻole ia e hoʻololi i ke kino

waiwai o ka mea metala. He maʻalahi ke kaʻina hana ʻaʻole i hoʻololi ʻia nā mea metala.

B: Ke kuʻi ʻana

ʻO ka lua o ka ʻanuʻu, ʻo ia ka ninini ʻana i ka pauka metala i loko o kahi pahu i hoʻomākaukau mua ʻia i hiki ai iā ʻoe ke hana i ka kānana.

Hoʻokumu ʻia ka hui kānana ma ka lumiwela a ma lalo o ke kahakaha ʻana. Ka nui o ke kaomi

pili i ka metala āu e hoʻohana nei, no ka mea, ʻokoʻa ka elasticity o nā metala.

Ma hope o ka hopena o ke kaomi kiʻekiʻe, hoʻopili ʻia ka pauka metala i loko o ka mold e hana i kahi kānana paʻa.Ma hope o ka

kiʻekiʻe-pressure hopena kaʻina hana, hiki iā ʻoee kau i ka kānana metala i hoʻomākaukau ʻia i loko o kahi umu wela wela.

C: Kiekie-mehana Sintering

Ma ke kaʻina hana sintering, hoʻohui ʻia nā ʻāpana metala e hana i hoʻokahi ʻāpana me ka hiki ʻole i ka helu heheʻe.

He ikaika kēia monolith,ʻoʻoleʻa, a porous kahi kānana e like me ke metala.

Hiki iāʻoe ke hoʻomalu i ka porosity o ka kānana ma ke kaʻina hana e like me ke kahe o ka ea a iʻole ka wai e kānana.

ʻO ka hoʻohālikelike ʻia ʻana o ka papa media sintered ua like ia me ka mean flow pore, a i ʻole ka nui o ka pore awelika o ka kānana.

ʻO nā media metala i hoʻopaʻa ʻiahāʻawi ʻia i nā papa 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 a me 100. ʻO ka helu kānana ma

ʻO ka wai no nā māka media 0.2 a 20 ma waena o 1.4 a me 35 µmpaa loa. Ka helu kānana ma nā pae kinoea

mai ka 0.1 a i ka 100 µm loa.

No ke aha e hoʻohana ai i ka Sintering Metala e hana i kāna kānana?

He nīnau maikaʻi kēia, no ke aha e hoʻohana ai i ka metala e hana i kahi kānana?

He maʻalahi ka pane, a ʻoiai he nui nā kumu, ʻo ke kumukūʻai ka mea nui loa.

No ke aha ke kumu kūʻai?

ʻAe, ʻo ka metala sintered he hale paʻa a hiki ke hoʻohana hou ʻia, maʻemaʻe, a hoʻohana i nā manawa he nui.

A ʻo kekahi, loaʻa nā metala ʻokoʻa i nā waiwai kino a me nā kemika a ʻaʻole hiki ke pohō.

ʻO ia ke kumu i hoʻohana ʻia ai nā kānana Sintered i nā ʻoihana like ʻole.

He aha nā koho mea waiwai noNā kānana Sintered?

Me ka holomua hoʻomau o ka pauda metallurgy ʻenehana, ʻoi aku ka nui o nā koho

nā mea no nā kānana metala sintered,

Hiki iā ʻoe ke koho mai nā metala ʻē aʻe a me nā alaloa e hoʻokō i nā koi kūikawā o ke kiʻekiʻe

ka wela a me ke kaomi, corrosionke kū'ē a me nā mea'ē aʻe, nā mea metala nui e like me:

-

Kānana kila kila; 316L, 304L, 310, 347 a me 430

-

keleawe

-

Inconel® 600, 625 a me 690

-

Nickel200 a me Monel® 400 (70 Ni-30 Cu)

-

Titanium

-

Alloys

E hoʻohana hou ʻia ka metala i kēia mua aku.

8-Main Pono o Sintered Metal kānana

1. ) Ke kū'ē i ka corrosion

ʻO ka hapa nui o nā metala ke kūpaʻa i ka corrosion, e like me sulfides, hydride, oxidation, etc.

2.) ʻOi aku ka maikaʻi o ka wehe ʻana i nā mea haumia

ʻO ka hoʻoponopono ʻana i ka porosity o ka pahu pahu i ka wai e hiki ai iā ʻoe ke hoʻokō i ka mea kūpono

kānana āu e makemake ai a loaʻa i kahiwai haumia ʻole. Eia kekahi, no ka mea, ʻaʻole ʻino ka kānana,

ʻAʻole i loaʻa ka hopena o ka kānana i ke aloo na mea haumia iloko o ka wai.

3. ) Ha'alulu wela ki'eki'e

I loko o ke kaʻina hana, hana ʻia ka wela kiʻekiʻe, a me nā waiwai kino o

kōkua kēia mau metala i ka hoʻopaʻa ʻanapuiwa wela nui o ke kānana. ʻO ka hopena, hiki iā ʻoe ke hoʻohana i kēia mau mea

nā kānana ma kahi ākea o nā noi ma muli oka laulā wela o ka noi.

ʻO ka haʻalulu wela nui hoʻi e hōʻoia i ka kānana wai kūpono me ka hopohopo ʻole

ka wela o ka noi.

4、) Hoʻokuʻu i ke kaomi kūpono

Akānana metala sinteredhiki ke mālama i ke kaomi wai i kāu noi, pēlā e hōʻoia ai

hana nui loa.

Hiki ke hoʻopōʻino i kāu noi ke hāʻule iki.

5. ) Ka Mahana a me ka Paʻi Paʻi

Hiki iā ʻoe ke hoʻohana i kēia kānana i nā noi me nā mahana kiʻekiʻe a me nā kaomi ʻole

hopohopo e pili ana i kāu mea kānana.

Ke hoʻohana nei i nā kānana metala sintered i ke kaʻina hana o nā hopena kemika a me ke kinoea

hōʻoia nā mea kanu lapaʻau iā ʻoeloaʻa nā hopena kānana maikaʻi loa.

6. ) ʻOʻoleʻa a kūpaʻa i ka Nahaha

ʻO kekahi pōmaikaʻi o ka hoʻohana ʻana i kahi kānana metala sintered ʻo ia ka ikaika a kūpaʻa

haʻihaʻi.

I ka wā o ka hana ʻana, hiki ke hoʻopaʻa ʻia nā metala i nā mahana maikaʻi

malalo o ka helu hehee.

ʻO ka huahana i loaʻa he kānana metala paʻakikī hiki ke kū i nā ʻano like ʻole

kaiapuni paakiki.

No ka laʻana, hiki iā ʻoe ke hoʻohana iā ia i nā noi e koi ana i ka friction me ka makaʻu ʻole i ka haki.

7.) Hoʻomanawanui maikaʻi

ʻO ka hoʻomanawanui maikaʻi ʻo ia ka hiki i kāu kānana metala sintered ke kānana i kou wai me ka ʻole o ka pane ʻana.

Ke hoʻopau ʻia kāu kānana ʻana, e mālama ka kānana metala i hoʻopaʻa ʻia i kona mau waiwai kino.

Eia nō naʻe, e kōkua inā ʻoe e hōʻoia ʻaʻole e lilo ka metala āu e koho ai no kāu kānana

e hoʻopili me ka wai āu e kānana nei

8.) He laulā o Geometric Possibilities

Hiki iā ʻoe ke hauʻoli i ka nui o nā koho geometric. Hiki iā ʻoe ke hoʻokō

keia oiai e hookomo ana i ka paudai loko o ke kala i ka wā hana.

ʻO ka mold ka mea e hoʻolālā i kāu kānana.

No laila, ua noa ʻoe e hana i ka hoʻolālā e like me kāu mau kikoʻī.

No ka laʻana, inā makemake kāu noi i kahi kānana liʻiliʻi, hiki iā ʻoe ke maʻalahi i ka hoʻolālā

e loaa ka mea liilii

kānana metala sintered.Pēlā nō, inā he hoʻolālā kūʻokoʻa kāu noi, hiki iā ʻoe ke maʻalahi

manipulate i ka manao ma kaponi i ka wā hana.

Pehea ka hana ʻana o nā kānana metala Sintered?

Hiki ke ʻōlelo ʻia kēia pilikia ke kumu hana o nā kānana metala sintered. Manaʻo ka poʻe he nui

o keia ninaupaʻakikī loa e pane, ʻaʻole.Mahalo paha ʻoe i kēia, akā ʻo ʻoe paha

ʻaʻole ma hope o ka heluhelu ʻana i kaʻu wehewehe.

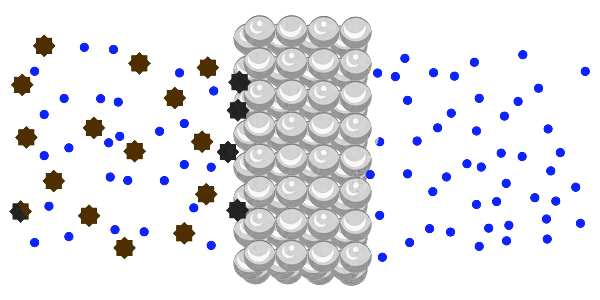

ʻO nā kānana metala sintered he mau kānana pono loa. ʻO ka hōʻiliʻili o nā mea haumia aia ma ka ʻili o

ka wai; i ka manawa o kahele ka wai ma ke kānana metala, kanui nā ʻāpana a me nā mea haumia

waiho ʻia ma kekahi ʻaoʻao o ka pahu pahu, akā i ka wāke koho ʻana i kahi pae kānana kūpono no kāu wai, ʻoe

pono e hōʻoia i kēlāhiki iā ia ke kānana i nā koi.

* Aia kēia mau koi

1. Hiki ke hoʻopaʻa ʻia ka mea hoʻopaʻa i hope

2. Paʻi Paʻi

No ka hāʻule ʻana o ke kaomi, pono ʻoe e noʻonoʻo i kekahi mau kumu.

Aia kēia mau mea

AʻO ka viscosity wai, ka wikiwiki o ka wai i ka wā e kahe ana ma ka mea kānana, a me nā ʻano mea haumia.

BʻO nā hiʻohiʻona hoʻohaumia e pili ana i ke ʻano o ka ʻāpana, ka nui, a me ka nui.

Inā paʻakikī a maʻamau ke ʻano o ka mea haumia, e hana ana i kahi keke paʻa, a laila kūpono ka kānana ʻana.

*Ma muli o ka pono o ka kānana metala Sintered

1.hāʻule ka piʻi nui a hiki i kahi i hiki ai ke kaomi piha.

2. ke kahe mau o ka wai.

Hiki iā ʻoe ke hoʻokō i nā kūlana hopena ma o ka hoʻopaʻa ʻana i nā mea haumia e piʻi aʻe i kahi e hāʻule ai ke kaomi wai.

Ke hāʻule mau nei kēia kaomi a hiki i ka hāʻule kiʻekiʻe no ka viscosity i hāʻawi ʻia a me ke koi kahe kahe.

ʻO kekahi pilikia koʻikoʻi ʻo ka holoi ʻana i hope o ka kānana, i hana ʻia ma ke kaomi ʻana i ke kinoea i ka pale a me ka wikiwiki

e wehe ana i ka pahu hoʻokuʻu hopee like me ka hana ʻana o ka holoi hope.

ʻO kahi ʻokoʻa ʻokoʻa puʻe koke hoʻohuli kiʻekiʻehana ʻia. Hoʻopau maikaʻi ia i nā mea haumia mai ka kānana

ʻeleʻele ʻili. ʻO ka hopeʻO ke kahe o ka wai maʻemaʻe ma o ka mea kānana e wehe i nā mea haumia a kuhikuhi iā lākou

mai loko mai o ka kānana.

ʻO ka piʻi mau ʻana o ka hāʻule kaomi e hōʻike ana i ka hāʻawi like ʻana o ka nui o nā mea haumia.To

hoʻokō kūlikehana, pono ʻoe e hōʻoia i ka paʻa o ka hāʻule kaomi o ka mea kānana.Inā ka mahana

o ka hoololi wai, pilika viscosity o ka wai. I kēia hihia, hāʻule ke kaomi ma luna o ka kānanamea makemake

hoʻonui a loaʻa ʻole ka hopena kānana.

No laila, ponoʻoe e mālama i ka mahana hana o ka kānana i ka wā o ka kānana a me

hōʻoia i kaka mahana o ka wai a me ke kaomi.Ke hoʻomaʻemaʻe i ka kānana, pono ʻoe e hahai i ka

ke kaʻina hana holoi hope.

Pehea ka hana ʻana o nā kānana metala Sintered?

Hiki iā ʻoe ke hoʻomaopopo maʻalahi ke nānā ʻoe i ka hahaiKiʻi kumu hana

E like me ka mea nui8-Na anoo Kakumu hana o ka kānana metala, lana ka manaʻo e kōkua ia iā ʻoe

hoomaopopo hou akuno ka mea peheahiki ke kōkua ke kānana metala sinteredno ka wai kānana, kinoea a me ka leo.

1.) Liquid & Gas Filtration / Separation

Hiki i nā kānana Sintered Metal ke hōʻemi a hoʻopau loa i nā mea ʻāpana mai ke kinoea a i ʻole ka wai.

Hiki i nā mea ʻāpanae hoʻokomo akā ʻaʻole i kaupalena ʻia i nā ʻāpana i hoʻokuʻu ʻia (sediment, chip metala, paʻakai, etc.),

nā algae, bacteria, fungi spores, a me ka makemake ʻolenā mea hoʻohaumia kino/kemika. Metala kānana pore nui

Hiki iā ia ke hana mai ka 0.2 µm - 250 µm.

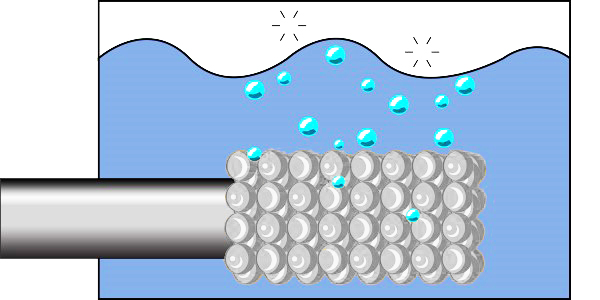

2.)Sparger

ʻO kekahi o nā polokalamu Sparging:

ʻO ka Soda Carbonization

ʻO ka hoʻonaʻauao pia

OxygenKa Wehe ana i na Aila Ai

ʻO ka sparging ka hoʻokomo ʻana o ke kinoea i loko o ka wai. Hoʻohana ʻia e wehe i kahi kinoea hoʻoheheʻe ʻole ʻia

(ka wehe ʻana o ka oxygen) a i ʻolehe wai hoʻoheheʻe ʻia. Hiki iā ia ke hoʻohana e hoʻokomo i ke kinoea i loko o kahi wai (carbonization).

ʻO ka sparging kuʻuna i hana ʻia nā ʻōhūme ke anawaena o 6 mm. Hiki i ka sparging kānana PM ke ʻoi aku ka liʻiliʻi

opuu anawaena, pela e hoonui ai i ka ili onā ʻōhū e hana ana i ka sparging ʻoi aku ka maikaʻi

noi ma ka hoemi ana i ka manawa hana.

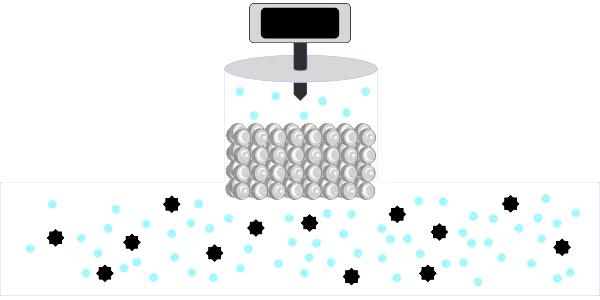

3.) Puka Hanu

Hoʻohana ʻia nā kānana metala Sintered e like me nā puka hanu i loko o nā cylinders, gearboxes, manifolds, hydraulic system,

nā waihona, a me nā mea ʻē aʻeʻōnaehana. Hiki i nā puka makani ke hoʻohālikelike i ke kaomi a me ka ea/ea i loko a i waho o kahi ʻōnaehana

oiai e keakea ana i na mea pakahi maike komo ʻana i ka ʻōnaehana. Hiki ke holoi ʻia nā kānana metala no ka wehe ʻana i nā ʻāpana

mea, hāʻawi iā lākou i ke ola lōʻihi ma ke ʻano he hanuvent ma mua o nā mea kānana ʻē aʻe.

4.) Palena Sensor

Hiki i nā kānana Sintered Metal ke pale aku i nā mea uila ma ke ʻano he uhi, e like me nā thermometers,

nā mea ʻike like ʻole,kīnā ʻāpana o nā ʻōnaehana olakino, a me nā huahana koʻikoʻi ʻē aʻe mai ka wai,

wai, sediment, lepo, aka piʻi ʻana o ke kaomi.

5.) Mana Kahe ( Throttling / Dampening )

Hiki i kahi kānana sintered kūikawā ke hoʻomalu i ke kahe ʻana i loko o kahi ea, kinoea, ʻūhā, a me ka ʻōnaehana kahe wai. ʻO ka

ʻaʻahu kānananui poree ʻae i ka hoʻoponopono ʻana i ke kahe mau ʻana a me ka pale ʻana i nā kiwi, nā ʻike,

a me nā mea ʻē aʻe ma laloi ka ʻōnaehana mainā mea haumia. Hoʻohana ʻia ka mana kahe ma ia ʻano

nā noi e like me nā manawa pneumatic, ka mana hoʻolako kinoeanā mea, a me ka manawa lohinā mea i loko

nā noi kaʻa.

6.) Nā mea hoʻoheheʻe ea

Hiki ke hoʻopaʻa ʻia a hoʻopaʻa ʻia paha nā kānana Sintered i kekahi mea pono, e ʻae iā lākou e hana ma ke ʻano he

mea hoʻoheheʻe ʻia.ʻAʻole hiki i ka kānana ke pale wale i nā solenoids a me nā manifolds mai nā mea haumia i loko o ka

ʻōnaehana akā hōʻemi pū i ka walaʻaupae o ka pauku mai ka ʻōnaehana. ʻO nā kānana hoʻoheheʻe ea

kekahie hoʻohaʻahaʻa i ke ea e puhi mai ana mai ka ʻōnaehana, ʻo ia hoʻihōʻemi i nā mea haumia e lele ana, Hoʻomalu

ke kaiapuni.

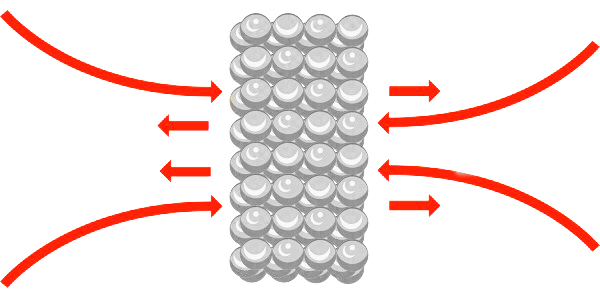

7.) Kahe / Paʻi Kaulike

Hiki i nā kānana Sintered ke hoʻohālikelike a hoʻomalu i ka kahe kahe o ka ʻōnaehana a me ke kaomi. Mālama ka hoʻohālikelike

nā ʻōnaehana kūʻē i ka piʻi ʻanao ka wai a hana i ka holo like ʻana i ka neʻe ʻana o ke kinoea a i ʻole ka wai

nā pores like ʻole.

He aha nā kānana Sintered i hoʻohana ʻia no?

No kēia nīnau, ʻoiaʻiʻo e nīnau hou aku ka poʻe He aha ka hoʻohana ʻana o nā kānana metala sintered?

Ma hope o kēlā kaʻina hana paʻakikī, ma hea kahi e hoʻohana ʻia ai nā pahu kānana metala sintered?

ʻO ka ʻoiaʻiʻo hiki iā ʻoe ke loaʻa i kēia mau kānana ma nā ʻoihana like ʻole.

Loaʻa nā noi maʻamau i kēia mau mea.

1) Ka hana ʻana i nā kemika

Hiki iā ʻoe ke loaʻa nā kānana metala sintered i loko o ka ʻoihana hoʻoheheʻe kemika a me nā ʻoihana hoʻoili kinoea, me ka

ʻoihana nuklea.ʻO ka ʻinoʻino, ka wela kiʻekiʻe, a me ka pane ʻole ʻana i nā kemika e hana i ka metala sintered

kānana i kahi pono ʻokoʻa ma

ka ʻoihana hana kemika.

2) Hoʻomaʻemaʻe ʻaila

No ka hoʻomaʻemaʻe ʻaila, e kānana pono i nā wahie like ʻole

Pono mākou e hoʻohana i nā kānana metala like ʻole e like me ka pae degere e hoʻopau i ka kānana o ka

wahie kiko'ī maika waihona hānai.ʻAe, hiki i nā kānana metala sintered ke kōkua iā ʻoe e hoʻokō i kēia pahuhopu.

No ka mea, ʻaʻole hana kemika nā kānana metala me ka wahie.

No laila, e kaʻawale ka wahie kikoʻī i nā mea haumia ma hope o ke kānana ʻana.

Eia hou, hiki iā ʻoe ke hoʻohana iā ia ma nā mahana a hiki i 700 °, ka mea maʻamau i ka hoʻomaʻemaʻe ʻaila.

3.) Ka hana mana

Pono ka hana ʻana o ka mana hydroelectric i ka hana mau o ka turbine. Eia naʻe, ʻo ka

kaiapuni iʻo ia ka turbineʻO ka hana pinepine e koi i ka kānana no ka loaʻa ʻana o kahi kino wai i loko

ʻaʻohe haumia o ka turbine.

Inā hoʻopiha ʻia ka turbine me nā mea haumia, e makani ia a pale i ka ʻōwili ʻana o ka turbine,

a laila e hana ka turbineʻaʻole hana i ka uila. Hiki iā ʻoe ke hoʻohana i nā kānana metala sintered e hōʻoia

hana mana kūpono a maikaʻi.

Hoʻohana ʻia kēia mau kānana e hana i ka uila ma ke kānana ʻana i ka wai mai ka turbine.

No ka mea, ʻaʻole lākou e hoʻopau ʻia e ka wai, e hana ka turbine no ka manawa lōʻihi.

4.) Hana kinoea maoli

ʻO kekahi wahi koʻikoʻi o ka noi no nā kānana metala sintered ʻo ka hana kinoea.

He mea maikaʻi loa nā kānana metala Sintered i ka hana kinoea no ka mea ʻaʻole lākou e pane me ke kinoea,

a hiki iā ʻoe ke hoʻohana iā lākouma nā kaiapuni like ʻole.

5.) Meaʻai a mea inu

Hoʻopuka nā kānana metala i nā meaʻai a me nā wai i loko o ka ʻoihana meaʻai a me ka mea inu.

Hoʻomaʻamaʻa maikaʻi nā kānana metala a pale i kēia mau meaʻai mai ka holoi ʻia ʻana i ka wā e hana ai.

ʻO ka pōmaikaʻi o nā kānana metala like ʻole, ʻaʻole lākou e hana me nā meaʻai a mea inu paha.

Ke hoʻohana nei i kēia mau kānana e hōʻoiaʻiʻo i ka maikaʻi o kāu kaʻina hana.

9. Pehea ke anoKānana Metala SinteredHiki iā HENGKO ke hoʻolako ?

HENGKO lako lako 316L, 316 a me keleawe sintered metala filers. ʻano nui e like me ka papa inoa:

1.Kānana kila kilaDisc,

2.KūleʻaKānana kilaPaipu,

3.Kūleʻa Kānana kilaPāpā,

4.Kānana kila kilaNā kīʻaha,

etc., nā ʻano like ʻole e pono ai kāu papahana.

ʻOiaʻiʻo, hoʻolako mākoulawelawe OEM

1.OEMKinohi:Disc, kīʻaha,Paipu, Papa ect

2.HoʻopilikinoNui, Kiʻekiʻe, Laulā, OD, ID

3.Ka nui o ka pore /Aperturesmai 0.1μm - 120μm

4.Hoʻopilikino ʻokoʻa Mānoanoa

5. ʻO ka mono-layer, ka multi-layer, nā mea i hui ʻia

6.Hoʻolālā i hoʻohui ʻia me 304 hale kila kila

No kāu kikoʻī OEM hou aku, e ʻoluʻolu e kelepona iā HENGKO i kēia lā!

Loaʻa i kekahi mau nīnau e like me ka ʻike ʻana i nā kikoʻī hou aku no ka Humidity Monitoring Sensor,

E ʻoluʻolu e hoʻokaʻaʻike mai iā mākou i kēia manawa.

Hiki iā ʻoeE hoʻouna mai iā mākou i ka leka uilaE like me ka hahai pololei ʻana:ka@hengko.com

E hoʻihoʻi mākou me nā hola 24, mahalo no kou hoʻomanawanui!

E hoʻouna i kāu leka iā mākou:

Ka manawa hoʻouna: ʻAukake-20-2022